UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

(Mark One)

☒ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended DECEMBER 31, 2015

Or

☐TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from TO

Commission File Number: 001-36046

AXOGEN, INC.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

MINNESOTA

|

|

41-1301878

|

|

(State or other jurisdiction of

|

|

(I.R.S. Employer

|

|

incorporation or organization)

|

|

Identification No.)

|

|

|

|

|

|

13631 Progress Blvd., Suite 400 Alachua, FL

|

|

32615

|

|

(Address of principal executive offices)

|

|

(Zip Code)

|

Registrant’s telephone number, including area code: (386)-462-6800

|

|

|

|

Securities registered pursuant to Section 12(b) of the Act:

|

Common Stock, par value $0.01 per share

|

|

|

(Title of class)

|

|

Securities registered pursuant to Section 12(g) of the Act:

|

None

|

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically and posted in its corporate website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☒

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

|

|

|

|

|

Large accelerated filer ☐

|

|

Accelerated filer ☐

|

|

|

|

|

|

Non-accelerated filer ☐

|

|

Smaller reporting company ☒

|

|

(Do not check if a smaller reporting company)

|

|

|

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☒

As of June 30, 2015, the value of the voting and non-voting common equity held by non-affiliates of the registrant was approximately $57,895,176 based upon the last reported sale price of our common stock on the NASDAQ Capital Market.

The number of shares outstanding of the registrant’s common stock as of February 25, 2016 was 29,984,591 shares.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Registrant’s definitive proxy statement for its 2016 annual meeting of shareholders are incorporated by reference into Part III of this Form 10-K to the extent stated herein. Such proxy statement will be filed with the Securities and Exchange Commission within 120 days after the fiscal year ended December 31, 2015.

FORWARD-LOOKING STATEMENTS

From time to time, in reports filed with the Securities and Exchange Commission (including this Form 10-K), in press releases, and in other communications to shareholders or the investment community, AxoGen, Inc. (the “Company”, “AxoGen”, “we” or “our”) may provide forward-looking statements, as defined in the Private Securities Litigation Reform Act of 1995, concerning possible or anticipated future results of operations or business developments. Words such as "expects", "anticipates", "intends", "plans", "believes", "seeks", "estimates", "projects", "forecasts", "continue", "may", "should", "will" variations of such words and similar expressions are intended to identify such forward-looking statements. The forward-looking statements may include, without limitation, statements regarding our growth, our 2016 guidance, product development, product potential, financial performance, sales growth, product adoption, market awareness of our products, data validation, our visibility at and sponsorship of conferences and educational events. The forward-looking statements are subject to risks and uncertainties, which may cause results to differ materially from those set forth in the statements. Forward-looking statements in this Form 10-K should be evaluated together with the many uncertainties that affect the Company’s business and its market, particularly those discussed in the risk factors and cautionary statements in the Company’s filings with the Securities and Exchange Commission, including as described in “Risk Factors” included in Item 1A of this Form 10-K. Forward-looking statements are not guarantees of future performance, and actual results may differ materially from those projected. The forward-looking statements are representative only as of the date they are made, and the Company assumes no responsibility to update any forward-looking statements, whether as a result of new information, future events or otherwise.

PART I

ITEM 1. BUSINESS

General

We are a leading medical technology company dedicated to peripheral nerve repair. We provide products and education to improve surgical treatment algorithms for peripheral nerve injuries. Our portfolio of regenerative medicine products is available in the United States, Canada and several other countries and includes Avance® Nerve Graft, an off-the-shelf processed human nerve allograft for bridging severed nerves without the comorbidities associated with a second surgical site, AxoGuard® Nerve Connector, a porcine submucosa extracellular matrix (“ECM”) coaptation aid for tensionless repair of severed nerves, and AxoGuard® Nerve Protector, a porcine submucosa ECM product used to wrap and protect injured peripheral nerves and reinforce the nerve reconstruction while preventing soft tissue attachments. Along with these core surgical products, we also offer the AxoTouchTM Two-Point Discriminator and expect to launch in March 2016 the AcroVal™ Neurosensory and Motor Testing System. These evaluation and measurement tools assist healthcare professionals in detecting changes in sensation, assessing return of sensory, grip and pinch function, evaluating effective treatment interventions, and providing feedback to patients. The introduction of our evaluation and measurement products further reflects our commitment to bring best practices to the treatment of peripheral nerve conditions.

Peripheral nerves provide the pathways for both motor and sensory signals throughout the body and their damage can result in the loss of muscle function and/or feeling. Nerves can be damaged in a number of ways. When a nerve is cut due to a traumatic injury or surgery, functionality of the nerve may be compromised, causing the nerve to no longer carry the signals to and from the brain to the muscles and skin. This type of injury generally requires a surgical repair. The traditional gold standard has been to either suture the nerve ends together directly without tension or to bridge the gap between the nerve ends with a less important nerve surgically removed from elsewhere in the patient’s own body referred to as nerve autograft. In addition, compression on a nerve or blunt force trauma can cause nerve injuries that alter the signal conduction of the nerve and may require surgical intervention.

In order to improve the options available for the surgical repair and regeneration of peripheral nerves, AxoGen has developed and licensed regenerative medicine technologies. AxoGen’s innovative approach to regenerative medicine has resulted in first-in-class products that it believes are redefining the peripheral nerve repair market. AxoGen’s products are used by surgeons during surgical interventions to repair a wide variety of nerve injuries throughout the body. These injuries range from a simple laceration of a finger to a complex brachial plexus injury (an injury to the network of nerves that originate in the neck) as well as nerve injuries caused by dental and other surgical procedures. Avance® Nerve Graft provides surgeons an implant with the micro-architecture of a human nerve. This structure is essential and allows for bridging nerve gaps or discontinuities up to 70mm in length. Additionally, Avance® Nerve Graft has product and sales synergies with AxoGuard® Nerve Protector and AxoGuard® Nerve Connector. AxoGuard® products provide the unique features of pliability, suturability, and translucence for visualization of the underlying nerve, while also allowing the patient’s own cells to incorporate into the extracellular matrix to remodel and form a tissue similar to the outermost layer of the nerve (nerve epineurium).

Regenerative Medical Products Industry

Regenerative medical products enable the repair, restoration, replacement or regeneration of tissue or organ systems of the body. Regenerative medical products are becoming common in various medical arenas because they have been shown to be effective repairing injured or defective tissues, such as bone, tendons, dermis and other tissues of the body. Surgeons utilize regenerative medical products because they can provide the complex structure required for implant integration and regeneration in the body.

We believe the primary driver of sustained growth in the regenerative medical product market is continued favorable efficacy as compared to autograft tissue and synthetic medical products, and a wider understanding of this advantage by practitioners. Repair with nerve autograft requires a secondary recovery procedure to remove tissue from another location of the patient’s body to repair the injured area and results in loss of function at the site of donation.

Further, nerve autograft may also be costly and time consuming and may result in complications at the second surgical site such as infection. In addition to processed nerve allograft (Avance® Nerve Graft), alternatives to nerve autograft include hollow-tube synthetic or collagen-based medical products that are designed to provide some restoration of function but may be limited by mechanisms of nerve healing and/or biocompatibility with the body. Regenerative medical products often provide more desirable conditions for reconstruction and regeneration of tissue, creating a superior solution for patients and physicians. AxoGen follows this trend, providing regenerative medical products for peripheral nerve repair.

Regenerative medicine products typically consist of and rely on:

|

i.

| |

A scaffold or ECM to support the cells and/or provide the architecture of the tissue: and/or |

|

ii.

| |

Cells to regenerate or recellularize the scaffold. |

AxoGen’s regenerative products are scaffolds, and the patients’ own body provides the cells to regenerate or recellularize these scaffolds.

Peripheral Nerves and Their Regeneration

The peripheral nervous system, or PNS, consists of nerves that either extend outside of, or reside outside of, the central nervous system (primarily the brain and spinal cord). Peripheral nerves provide the pathway for signals between the central nervous system and target organs, regulating movement (motor nerves) and touch (sensory nerves). Therefore, if a peripheral nerve is crushed, severed, or otherwise damaged, its ability to deliver signals to the target organs is eliminated, or significantly reduced, and could result in a loss of sensation and/or functionality. The axon portion of the nerve cell, consisting of cell cytoplasm and resembling a hair-like fiber, carries signals from the cell body to the target organ. Axons can be quite long, even exceeding one meter, but are only a few micrometers in diameter. A typical nerve consists of hundreds of axons that lie within long, thin tubes (endoneurial tubes). Analogous to a wiring cable, these endoneurial tubes are bundled together in groups called fascicles, and each nerve may contain numerous fascicles. This sheath structure provides protection for the axons and support for regeneration in the event of injury. Nerve injury occurs when a sufficient number of axons have been crushed or transected (severed), thereby disrupting signals to the target motor or sensory organ.

Given the right conditions, peripheral nerves have the ability to regenerate. Regenerating axons require the proper environmental conditions including structure and guidance of axons in a tension and compression free environment. In an untreated severe crush injury or transected nerve, errant axons that are not guided by the nerve sheath structure, or other mechanism, can form painful and ineffective nerve proliferation (neuromas). This can then require revision surgery to relieve pain or bring back sensory and/or motor functionality. Therefore, the surgical treatment of nerve injuries is typically focused on restoring nerve functionality by providing structural guidance to regenerating axons while protecting the nerve to alleviate compression and tension.

Peripheral Nerve Regeneration Market Overview

Peripheral nerve injury (“PNI”) is a major source of disability impairing the ability to move muscles or to feel normal sensations. Failure to treat nerve damage can, in severe cases, lead to full loss of sensation and/or function, pain and, sometimes, amputation. Many peripheral nerve injury patients who receive treatment do not optimally recover. They may suffer from both reduced, or no, muscle strength, and reduced, or no, sensitivity and pain.

Every day patients suffer traumatic wounds to peripheral nerves severe enough to require surgical treatment, including injuries from motor vehicle accidents, power tool injuries, gunshot wounds, dislocations, fractures, lacerations, or other forms of penetrating trauma. The peripheral nerves commonly injured from these traumas include the digital, median, ulnar, radial, facial, spinal accessory and brachial plexus nerves. Traumatic PNI described herein, and excluding Oral and Carpal Tunnel defined below, is referred to by AxoGen as occurring in the “Extremity” PNI market.

Beyond traumatic injury to nerves described above, nerve damage also occurs due to surgical intervention. Some of these surgical nerve injuries can occur during dental and oral surgery procedures such as third molar extractions,

placement of dental implants and removal of tumors during which an injury may be caused to one or more sections of the trigeminal nerve (“Oral”). This can result in numbness in certain areas of the face and mouth. Finally, nerves are also damaged or compromised due to compression injuries. For instance, severe and recurrent carpal tunnel cases may result in complications and damage to the nerve that requires surgical intervention and protection of the nerve. We refer to PNI caused by carpal tunnel syndrome as “Carpal Tunnel”. Additional surgical procedures where nerves can be injured include the removal of cancerous tissues or reconstructive surgery. For example, nerves may be injured or removed during a radical prostatectomy to remove prostate cancer and this nerve injury may result in impotence and incontinence. Further, breast cancer patients may have reduced sensation in the tissue used to reconstruct the breast after mastectomy.

In the cases where a nerve is severed and the gap between the two ends of the nerve is extremely small, the surgeon may be able to reconnect the nerve without tension through direct suturing using a coaptation aid (“Primary Repair”). When the gap in the nerve tissue is more than a few millimeters in length, the surgeon typically needs to use material to bridge the gap between the nerve ends to ensure a tension-free repair (“Gap Repair”). Historically for a Gap Repair surgeons have relied on a nerve autotransplantation (autologous nerve grafting or nerve autograft). In nerve autograft procedures, surgeons remove nerve from another part of the patient’s body, frequently the sural nerve from the back of the lower leg, to repair the damaged nerve. Nerve autografting is often effective in repairing a damaged peripheral nerve, but it presents a tradeoff — the surgeon can attempt to fix the damaged nerve but must create an additional nerve deficit at another location in the body. For example, a patient may opt to get movement and feeling back in their finger while losing some sensation in their foot. Additionally, the secondary surgery to obtain the needed nerve autograft also increases operating time, and thus medical expenses, and increases the risk of surgical site infection and other complications. In the case of extreme trauma where multiple nerves need to be repaired, it may not be possible to recover enough nerve from the patient to complete the Gap Repair. Further, nerve autograft tissue may not provide an appropriate diameter match with the diameter of the injured nerve stump, an important factor in a successful repair outcome.

Drawbacks of repair with autograft nerve eventually led to the development of hollow tube conduits, or hollow tube nerve cuffs for Primary and Gap Repair made of, for instance, bovine collagen or polyglycolic acid. The nerve cuff is typically an absorbable hollow tube that, unlike natural peripheral nerve, does not have internal microarchitecture and endoneurial tubes to support regenerating axons; as a result, it is deficient in the qualities that natural nerve possesses to support nerve regeneration across a gap. Hollow-tubes may also lack pliability and structural integrity needed when used around joints and may be difficult to use in a confined space. Clinical data has demonstrated that hollow tubes are most effective when used in very short gaps, what AxoGen defines as Primary Repair, and the reliability of successful nerve recovery diminishes as gap length increases.

The shortcomings of hollow-tubes for nerve repair limit where they may be used effectively. Thus, AxoGen believes the nerve repair market needs an alternative off-the-shelf product that offer other features such as a natural ECM scaffold and three-dimensional structure of a typical nerve for bridging nerve discontinuities without the comorbidities of an additional surgical site required for harvest of autograft nerve tissue. AxoGen believes its Avance® Nerve Graft and AxoGuard® Nerve Connector products address the market needs for both Gap and Primary Repair.

Compression on a nerve or blunt force trauma can also cause nerve injuries that may require surgical intervention. In these cases, the nerve is not severed and thus does not create the need for a Primary or Gap Repair. However, the surgeon may want to protect and isolate the nerve during the healing process. In these situations nerve protection is provided by wrapping the nerve (“Nerve Protection”).

AxoGuard® Nerve Protector is a porcine submucosa extracellular matrix used for Nerve Protection. Other Nerve Protection products are usually made from bovine collagen or polyglycolic acid and are typically absorbable. AxoGuard® Nerve Protector provides the unique features of pliability, suturability, and translucence for visualization of the underlying nerve, while also allowing the patient’s own cells to incorporate into the extracellular matrix to remodel and separate the nerve from the surrounding tissue.

Based on estimates prepared by AxoGen, it believes the United States PNI market for its current product portfolio for Extremity, Oral and Carpal Tunnel Revision is $1.6 billion (the “Market”). We estimate that the Extremity portion

of the Market is approximately $1.3 billion. The estimated size of the Extremity portion of the market is based upon epidemiological studies regarding the general number of trauma patients, physician interviews and incidence of PNI in the population. AxoGen believes each year in the U.S. more than 1.4 million people suffer traumatic injuries to peripheral nerves. AxoGen estimates that traumatic and non-traumatic injuries to peripheral nerves result in over 700,000 extremity nerve repair procedures (“Health”, United States, 2011, Publication of U.S. Department of Health & Human Services; Noble, et al. J of Trauma Injury Infection and Critical Care 1998; Kurt Brattain, MD, Magellan Medical Technology Consultants, Inc., Minneapolis, Minnesota 2013). AxoGen further estimated the portion of extremity nerve repair procedures that would be addressed by AxoGen’s Gap Repair, Primary Repair and Nerve Protection products and applied the average sales price of the AxoGen product appropriate to the procedure (Avance® Nerve Graft, AxoGuard® Nerve Connector and AxoGuard® Nerve Protector, respectively). As a result, AxoGen estimates that the market sizes, within the Extremity portion of the Market, for our Avance® Nerve Graft, AxoGuard® Nerve Connector and AxoGuard® Nerve Protector products are approximately $668 million, $161 million and $483 million, respectively.

AxoGen estimates that the Oral portion of the Market is approximately $129 million of the Market, based upon research that has indicated approximately 68,000 PNI occur in the U.S. each year that are related to third molar extractions, anesthetic injections and dental implants. (The Prophylactic Extraction of Third Molars: A Public Health Hazard: Jay W. Friedman, DDS, Health Policy and Ethics; Peer Reviewed; Friedman American Journal of Public Health; September 2007, Vol 97, No. 9, pp 1554 — 1559 — Journal of Oral Implantology, Vol. XXXVI/No. Five/2010; “Inferior Alveolar Nerve Injury in Implant Dentistry: Diagnosis, Causes, Prevention, and Management”; Ahmed Ali Alhassani, BDS - “Nerve Injuries after Dental Injection: A Review of the Literature”; Clinical Practice, July/August 2006, Vol. 72, No. 6, Miller H. Smith, BMedSc, DDS; Kevin E. Lung, BSc, DDS, MSc, FRCD(C)). AxoGen has applied the average sales price of the Avance® Nerve Graft and AxoGuard® Nerve Protector that address Oral PNI in order to derive the Oral portion of the Market.

AxoGen estimates that the Carpal Tunnel portion of the Market is approximately $160 million. According to literature, there are approximately 500,000 carpal tunnel relief surgeries performed annually in the U.S., and AxoGen assumes that 20% of such surgeries require revision procedures to address the recurrence of symptoms (“Vein-Graft Wrapping for the Treatment of Recurrent Compression of the Median Nerve”, Microsurgery 16:752-756 1995, Dean G. Sotereanos, M.D.). As a result, AxoGen estimates that approximately 100,000 carpal tunnel revision surgeries are performed each year in the U.S. to address the recurrence of symptoms. These revision surgeries are required due to compression of the nerve due to soft tissue attachments from the surrounding tissue or tissue infiltration entrapping the nerve. To prevent additional recurrences, surgeons will opt to use a Nerve Protection product such as the AxoGuard® Nerve Protector. In order to derive the Carpal Tunnel portion of the Market, AxoGen multiplied the average sales price of our AxoGuard® Nerve Protector by the number of estimated carpal tunnel revisions.

AxoGen continues to look at expansion markets beyond those that AxoGen has defined as Extremity, Oral and Carpal Tunnel. In addition to these areas, AxoGen believes a market exists to treat nerves that are severed during the removal of both benign and cancerous tumors. For example, nerves may be injured or removed during a surgical prostatectomy to remove prostate cancer resulting in impotence and incontinence. Further, a patient who receives repair of peripheral nerves in the breast following a mastectomy and reconstruction, may avoid the reduced sensation typically experienced by many breast cancer patients. AxoGen believes that we will continue to identify market expansion opportunities for our current product portfolio.

AxoGen’s Product Portfolio

Overview of AxoGen’s Products

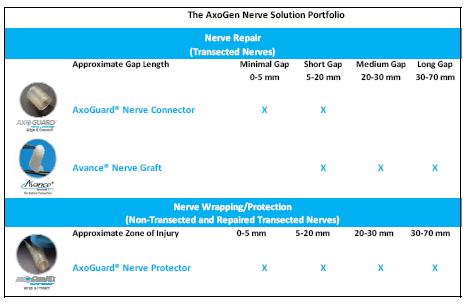

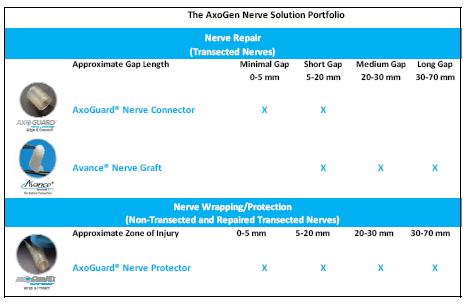

AxoGen’s proprietary products and technologies are designed to overcome fundamental challenges in nerve repair. AxoGen’s Avance® Nerve Graft is the alternative to autografts and other off-the-shelf nerve repair products for nerve gaps up to 70mm in length. AxoGuard® Nerve Connector is a coaptation aid for transected nerve injuries. AxoGuard® Nerve Protector completes the surgical repair portion of the product portfolio and is a protective wrap for nerves damaged by compression, or where the surgeon wants to protect and isolate the nerve during the healing process after

surgery. The AxoGen surgical repair product portfolio, depicted below, provides surgeons off-the-shelf solutions for a wide variety of peripheral nerve injuries.

Functional measurements play an important role in the evaluation of nerve function. It assists the healthcare professionals in detecting changes in sensation or muscle strength, assessing return of sensory or motor function, establishing effective treatment interventions, and providing feedback to the patients Standardized evaluation and measurement of nerve function is also an important part of identifying nerve injuries and determining treatment outcomes. AxoGen’s functional measurement products include the AxoTouch™ Two-Point Discriminator tool (for sensory function) and the AcroVal™ Neurosensory and Motor Testing System (for sensory and motor function) which will be launched in March 2016.

Avance® Nerve Graft

Avance® Nerve Graft is intended for the surgical repair of peripheral nerve discontinuities to support regeneration across the defect (a gap created when the nerve is severed). It is intended to act as a bridge in order to guide and structurally support axonal regeneration across a nerve gap caused by traumatic injury or surgical intervention. Avance® Nerve Graft is decellularized and sterile extracellular matrix (ECM) processed from human peripheral nerve tissue. AxoGen developed the Avance® Nerve Graft by following the guiding principle that the human body created the optimal nerve structure. AxoGen, through its licensing efforts and research, developed the Avance® process, a proprietary method for processing recovered human peripheral nerve tissue in a manner that preserves the essential structure of the ECM while cleansing away cellular and noncellular debris. Avance® Nerve Graft provides the natural nerve structure of an autograft and the ease and availability of an off-the-shelf product. AxoGen believes that Avance® Nerve Graft is the first off-the-shelf human nerve allograft for bridging nerve discontinuities. Avance® Nerve Graft is comprised of bundles of small diameter endoneurial tubes that are held together by an outer sheath called the epineurium. Avance® Nerve Graft has been processed to remove cellular and noncellular factors such as cells, fat, blood, axonal debris and chondroitin sulfate proteoglycans, (“CSPG”), while preserving the three-dimensional laminin lined tubular bioscaffold (i.e. microarchitecture), epineurium and microvasculature of the peripheral nerve. After processing, Avance® Nerve Graft is flexible and pliable, and its epineurium can be sutured in place allowing for tension-free approximation of the proximal and distal peripheral nerve stumps. The design results in a product that has clean and clear pathways for the regenerating axons to grow through. During the healing process, the body revascularizes and gradually remodels the graft into the patient’s own tissue while allowing the processed nerve allograft to physically support axonal regeneration across the nerve discontinuity.

With lengths up to 70 mm and diameters up to 5 mm, the Avance® Nerve Graft allows surgeons to choose the correct length for repairing the relevant nerve gap, as well as to match the diameter to the proximal and distal end of the severed nerve. The Avance® Nerve Graft is stored frozen and utilizes packaging that maintains the graft in a sterile condition. The packaging is typical for medical products so the surgical staff is familiar with opening the package for transfer of the Avance® Nerve Graft into the sterile surgical field. Such packaging also provides protection during shipment and storage and a reservoir for the addition of sterile fluid to aid in thawing the product. The Avance® Nerve Graft thaws in less than 10 minutes, and once thawed, it is ready for implantation.

The Avance® Nerve Graft provides the following key advantages:

|

·

| |

A three-dimensional bioscaffold for bridging a nerve gap; |

|

·

| |

No patient donor-nerve surgery, therefore no comorbidities associated with a secondary surgical site; |

|

·

| |

Available in a variety of diameters up to 5mm to meet a range of anatomical needs; |

|

·

| |

Available in a variety of lengths up to 70mm, to meet a range of gap lengths; |

|

·

| |

Decellularized and cleansed extracellular matrix that remodels into patient’s own tissue; |

|

·

| |

Structurally supports the body’s own regeneration process; |

|

·

| |

Handles similar to an autograft, and is flexible and pliable; |

|

·

| |

Alleviates tension at the repair site; |

|

·

| |

Three year shelf life; and |

AxoGuard® Nerve Connector

AxoGuard® Nerve Connector is a coaptation aid used to align and connect severed nerve ends in a tensionless repair. The product is in a tubular shape with an open lumen on each end where the severed nerve ends are placed. It is typically used when the gap between the nerve ends is less than 5mm in length. AxoGuard® Nerve Connector is made from a minimally processed porcine ECM which allows the body’s natural healing process to repair the nerve while its tube shape isolates and protects the injured nerves during the healing process. During healing, the material revascularizes and the patient’s own cells incorporate into the extracellular matrix product to remodel and form a tissue similar to the outermost layer of the nerve (nerve epineurium). AxoGuard® Nerve Connector is provided sterile, for single use only, and in a variety of sizes to meet the surgeon’s needs.

AxoGuard® Nerve Connector can be used:

|

·

| |

As an alternative to direct suture repair; |

|

·

| |

To relieve tension at the coaptation site of severed nerves; |

|

·

| |

To aid coaptation in direct repair, grafting, or cable grafting repairs; |

|

·

| |

To reduce the risk of forced fascicular mismatch; and |

|

·

| |

To reinforce the coaptation site. |

AxoGuard® Nerve Connector has the following advantages:

|

·

| |

Minimally processed porcine submucosa extra-cellular matrix product used to repair severed nerve tissue; |

|

·

| |

Alleviates tension at the repair site; |

|

·

| |

Revascularizes and remodels into the patient’s own tissue instead of degrading; |

|

·

| |

Reduces the number of required sutures (versus direct repair with suture) allowing for up to 40% reduced surgery time (Boechstyns, Jhand Surg. 2013;38:2405-2411); |

|

·

| |

Moves location of sutures away from the coaptation face; |

|

·

| |

Reduces potential for fascicular mismatch; |

|

·

| |

Allows visualization of underlying nerve tissue; |

|

·

| |

Available in 7 different diameters and 2 different lengths to address a variety of nerve repair situations; |

|

·

| |

Strong and flexible, easy to suture; and |

|

·

| |

Stored at room temperature with an 18-month shelf life. |

AxoGuard® Nerve Protector

AxoGuard® Nerve Protector is a product used to protect and wrap injured peripheral nerves and reinforce reconstructed nerve gaps while preventing soft tissue attachments. It is designed to protect and isolate the nerve during the healing process after surgery by creating a barrier between the nerve tissue and the surrounding tissue bed. The product is delivered in a slit tube format allowing it to be wrapped around nerve structures. AxoGuard® Nerve Protector is made from a minimally processed porcine ECM. During healing, the material revascularizes and the patient’s own cells incorporate into the extracellular matrix product to remodel and separate the nerve from the surrounding tissue. AxoGuard® Nerve Protector competes against off-the-shelf biomaterials such as reconstituted collagen as well as the use of the patients own tissue such as vein and hypothenar fat pad wrapping. AxoGuard® Nerve Protector is provided sterile, for single use only, and in a variety of sizes to meet the surgeon’s needs.

AxoGuard® Nerve Protector can be used to:

|

·

| |

Protect injured nerves or nerve repair sites from surrounding tissue; |

|

·

| |

Minimize risk of soft tissue attachments and entrapment in compressed nerves; |

|

·

| |

Protect nerves in a traumatized wound bed; and |

|

·

| |

Reinforce a coaptation site. |

AxoGuard® Nerve Protector has the following advantages:

|

·

| |

Minimally processed Porcine submucosa bioscaffold used to reinforce a coaptation site, wrap a partially severed nerve or protect nerve tissue; |

|

·

| |

Creates a protective layer that isolates and protects the nerve in a traumatized wound bed; |

|

·

| |

Revascularizes and remodels into the patient’s own tissue instead of degrading; |

|

·

| |

Easily conforms and provides 360 degree wrapping of injured nerve tissue; |

|

·

| |

Supports the body’s own natural wound healing; |

|

·

| |

Minimizes the potential for soft tissue attachments and nerve entrapment by physically isolating the nerve during the healing process; |

|

·

| |

Strong and flexible, plus easy to suture; |

|

·

| |

Is available in 5 different widths and 2 different lengths to address a variety of nerve repair situations; and |

|

·

| |

Stored at room temperature with an 18-month shelf life. |

AcroVal™ Neurosensory and Motor Testing System

AcroValTM Neurosensory and Motor Testing System is a device for evaluating patients with peripheral nerve conditions. We believe that an important step for improving patient outcomes is to support the standardized evaluation and measurement of nerve function. Today there is little consistency of measurement protocols. With the AcroVal™ system examiners will have digital, less subjective results for their patients with conditions like peripheral neuropathy, nerve compression syndromes, and transected nerves. Ultimately, we believe that standardization of evaluation and measurement techniques will facilitate comparison and interpretation of clinical results leading to better understanding and care for patients with peripheral nerve conditions.

Dr. A. Lee Dellon, a world-renowned peripheral nerve expert, developed the nerve functional evaluation and measurement system over 25 years ago. We acquired the rights to his device in 2015 and will launch the product in

March 2016. The AcroVal™ consists of three different devices designed to evaluate hand strength and neurosensory function:

|

·

| |

AcroGrip™ - hand grip strength measurement; |

|

·

| |

AcroPinch™ – pinch strength measurement; and |

|

·

| |

Pressure-Specified Sensory Device™ (PSSD) – somatosensory evaluation and measurement device |

AcroVal™ can be used to assist healthcare professionals:

|

·

| |

In detecting changes in sensation, pinch strength or grip strength; |

|

·

| |

Assessing return of sensory or motor function; |

|

·

| |

Establishing effective treatment interventions; and |

|

·

| |

Providing feedback to patients. |

AcroVal™ has the following advantages:

|

·

| |

Quantitative, electronic pre and post-intervention results; |

|

·

| |

Flexible format to allow for additional measurement devices; |

|

·

| |

Assessment of severity of nerve entrapment syndromes; |

|

·

| |

Reference database to provide baseline standards and support patient education. |

AxoTouchTM Two Point Discriminator

The AxoTouch™ Two-Point Discriminator tool can be used to measure the innervation density of any surface area of the skin. The discs are useful for determining sensation after a nerve injury, following the progression of a repaired nerve, and during the evaluation of a person with a possible nerve injury, such as nerve division or nerve compression.

The AxoTouch™ Two-Point Discriminator tool is a set of two aluminum discs each containing a series of prongs spaced between 2 to 15 millimeters apart. Additionally, 20 and 25 millimeter spacing is provided. A circular depression on either side of the disc allows ease of rotation. The discs can be rotated between a single prong for testing one-point and any of the other spaced prongs for testing two-point intervals.

AxoTouch™ Two-Point Discriminator has the following advantages:

|

·

| |

Capable of measuring the innervation density of any skin surface; |

|

·

| |

Portable and easy to use; |

|

·

| |

Strong aluminum design is resistant to bending; |

|

·

| |

Bright colors allow for clear discrimination between discs; |

|

·

| |

Clear numbering allows users to interpret results; and |

|

·

| |

Reusable carry case protects discs. |

Tissue Recovery and Processing for Avance® Nerve Graft

Avance® Nerve Graft Processing Overview

Over several years, AxoGen has developed the Avance® Process, an advanced and proprietary technique to process the Avance® Nerve Graft from donated peripheral nerve tissue. The Avance® Process requires special training over several months for each manufacturing associate who processes Avance® Nerve Grafts. The processing and manufacturing system for Avance® Nerve Graft has required significant capital investment, and we plan to make additional investments to continually improve our manufacturing and quality assurance processes and systems.

AxoGen’s Avance® Process, depicted below, consists of several steps, including peripheral nerve tissue recovery and testing, donor medical review and release, processing, packaging, and sterilization to meet or exceed all applicable U.S. Food and Drug Administration (the “FDA”), state, and international regulations and American Association of Tissue Banks (“AATB”) standards. As an FDA registered tissue establishment, AxoGen utilizes both its own personnel and a variety of subcontractors for recovery, storage, testing, processing and sterilization of the donated peripheral nerve tissue. Additionally, independent certified laboratories have been contracted by AxoGen and its subcontractors to perform testing. The safety of Avance® Nerve Graft is supported by donor screening, process validation, process controls, and validated terminal sterilization methods. The AxoGen Quality System has built in redundancies so that each Avance® Nerve Graft released for implantation meets our stringent quality control and product requirements.

Avance® Nerve Graft Tissue Recovery and Processing

AxoGen partners with FDA registered tissue establishments and AATB accredited recovery agencies or recovery agencies in compliance with AATB standards to recover human peripheral nerve tissue for Avance® Nerve Graft processing. After consent for donation is obtained, donations are screened and tested in detail for safety in compliance with the federal regulations and AATB standards on communicable disease transmission. AxoGen processes and packages Avance® Nerve Graft using its employees and equipment. From 2009 until February 2016 this processing and packaging was performed at LifeNet Health, Virginia Beach, Virginia (“LifeNet Health”). Business requirements of LifeNet Health led to their need for additional space and they notified AxoGen that AxoGen would need to transition out of the Virginia Beach facility on or before February 27, 2016. On August 6, 2015 Axogen entered into a License and Services Agreement with Community Blood Center (d/b/a Community Tissue Services) (“CTS”), Dayton, Ohio, an FDA registered tissue establishment. Processing of the Avance® Nerve Graft pursuant to the CTS agreement began in February 2016. The CTS agreement is for a 5-year term, subject to earlier termination by either party for cause, or after August 6, 2017 without cause, upon 18 months notice. Under the CTS agreement AxoGen pays CTS a facility fee for clean room/manufacturing, storage and office space. CTS also provides services in support of AxoGen’s manufacturing such as routine sterilization of daily supplies, providing disposable supplies, microbial services and office support. The service fee is based on a per donor batch rate. The CTS facility provides a cost effective, quality controlled and licensed facility. However, AxoGen could reproduce a manufacturing space that would meet its needs if it no longer continued its relationship with CTS. AxoGen’s processing methods and process controls have been developed and validated to ensure product uniformity and quality. Pursuant to the CTS agreement, AxoGen pays license fees on a monthly basis to CTS which total an annual amount of approximately $416,000.

Avance® Nerve Graft Packaging

After processing, each Avance® Nerve Graft is visually inspected and organized by size (length and diameter) into finished product codes. It is then packaged in individual medical grade clamshells and primary packaging. The outer pouch is the primary sterility and moisture barrier. The packaging operation is performed in a controlled environment at CTS.

Avance® Nerve Graft Sterilization and Labeling

After being processed and packaged, Avance® Nerve Graft is then irradiated and shipped to its Burleson, Texas distribution facility (the “Distribution Facility”). There the product receives its final labels and is released following a final stringent technical and quality review. Orders for Avance® Nerve Graft are placed with AxoGen’s customer care team and product is packaged and shipped from the Distribution Facility.

Avance® Nerve Graft Product Release

The AxoGen Quality System meets the requirements set forth under 21 CFR Part 1271 for Human Cells, Tissues and Cellular and Tissue-Based Products, including Good Tissue Practices (“GTP”) and is compliant with the 21 CFR Part 820 Quality System Regulations (“QSR”). AxoGen has established quality procedures for review of tissue recovery, relevant donor medical record review and release to processing that meet or exceed FDA requirements as defined in 21 CFR Part 1271, state regulations, international regulations and AATB standards. Furthermore, AxoGen utilizes validated processes for the handling of raw material components, environmental control, processing, packaging and terminal sterilization. In addition to ongoing monitoring activities for product conformity to specifications and sterility, product biocompatibility, shipping methods and shelf life have been validated in accordance with applicable industry standards.

Manufacturing of AxoGen Products Other Than Avance® Nerve Graft

Manufacturing for the AxoGuard® Product Line

AxoGuard® is manufactured by Cook Biotech Incorporated, West Lafayette, Indiana (“Cook Biotech”), which was established in 1995 to develop and manufacture tissue grafts utilizing porcine extracellular matrix technology. AxoGen decided to expand its portfolio of products and felt that the unique ECM material offered by Cook Biotech provided the combination of properties needed in nerve reconstruction. Cook Biotech’s ECM material is pliable, capable of being sutured, translucent and allows the patient’s own cells to incorporate into the extracellular matrix to remodel and form a tissue similar to the nerve’s epineurium. In August 2008, Cook Biotech entered into an agreement, amended in March 2012, with AxoGen to distribute its product worldwide in the field of the peripheral and central nervous system, but excluding use of the AxoGuard® product in the oral cavity for endodontic and periodontal applications and oral and maxillofacial surgery solely as they relate to dental, soft or hard tissue repair or reconstruction. The exclusion results in certain areas of AxoGen’s market expansion into the oral surgery market being limited to the Avance® Nerve Graft.

The Cook Biotech agreement runs through August 27, 2022. It requires certain minimum purchases, although through mutual agreement the parties have not established such minimums and to date have not enforced such provision, and establishes a formula for the transfer cost of the AxoGuard® products. Under the agreement, AxoGen provides purchase orders to Cook Biotech, and Cook Biotech fulfills the purchase orders.

Manufacturing for the AcroVal™ Neurosensory and Motor Testing System and AxoTouchTM Two Point Discriminator

The AcroVal™ Neurosensory and Motor Testing System and AxoTouchTM Two Point Discriminator are contract manufactured by Cybernetics Research Laboratories (“CRL”), Tucson, Arizona. CRL supplies the AxoTouch unpackaged and it is packaged at the Distribution Facility.

The AcroVal™ Neurosensory and Motor Testing System and AxoTouchTM Two Point Discriminator are contract manufactured by Cybernetics Research Laboratories (“CRL”), Tucson, Arizona. CRL supplies the AxoTouch unpackaged and it is packaged at the Burleson distribution facility. The Company and CRL are finalizing contracting for the AcroVal™. It is expected that CRL will provide the AcroVal™ to the Company’s Burleson distribution facility and AxoGen will perform final inspection and package for customer shipment. CRL will provide warranty service on behalf of the Company for the AcroVal™ and maintain certain levels of spare parts inventory for manufacturing and fulfillment of warranty work.

We believe CRL has capacity to support any future volumes of AcroValTM and AxoTouchTM.

Sales and Marketing

Overview

The AxoGen portfolio of nerve repair solutions, consisting of the Avance® Nerve Graft, AxoGuard® Nerve Connector and AxoGuard® Nerve Protector, offers a full range of products for surgical peripheral nerve repair needs. Its AcroVal™ Neurosensory and Motor Testing System and AxoTouchTM Two Point Discriminator evaluation and measurement tools assist healthcare professionals in detecting changes in sensation, assessing return of sensory function, establishing effective treatment interventions, and providing feedback to patients. AxoGen is focused on the developing market of peripheral nerve repair and regeneration, is committed to improving awareness of new surgical peripheral nerve repair options and is advancing evaluation capabilities for nerve issues, as well as building additional scientific and clinical data to assist surgeons and patients in making informed choices. AxoGen believes that there is an opportunity to rethink current approaches to nerve repair and that its approach will solidify its position as a leader in the field of products for peripheral nerve injuries. The following provides the key elements of AxoGen’s sales and marketing strategy.

Increase Awareness of AxoGen’s Products

Prior to the introduction of AxoGen’s portfolio of nerve repair products, surgeons had a limited number of options available for the surgical repair of nerve injuries. AxoGen entered the market to improve the standard of care for patients. Unlike other off-the-shelf options, all of AxoGen’s nerve repair products are composed of an extracellular matrix which remodels into the patient’s own tissue and provides physical support for the body’s natural healing process.

AxoGen intends to increase market share by improving awareness of nerve repair techniques and AxoGen’s products through the continued use of educational conferences and presentations, surgical resident and fellow training, scientific publications, and a knowledgeable and professional sales team. AxoGen works to increase usage with existing customers as well as expand the overall customer base. AxoGen is focused on plastic reconstructive surgeons and orthopedic and plastic surgeons who perform surgeries on patients suffering traumatic nerve injuries and who perform hand reconstructive surgeries and certain oral surgeons who repair oral nerve injuries.

Expand Clinical and Scientific Data Regarding the Performance of AxoGen Products

Generating clinical data is an important component of AxoGen’s marketing strategy. AxoGen will continue to accept patients in its RANGER® clinical study (defined below in “Government Regulations”), a utilization registry of Avance® Nerve Graft. Three publications and more than 44 scientific conference presentations have been generated to date from the registry. A multicenter prospective randomized comparative pilot study of hollow tube conduits and Avance® Nerve Graft has completed subject enrollment and outcome follow-up. A pivotal multicenter prospective randomized comparative pilot study of hollow tube conduits and Avance® Nerve Graft to support the transition to a BLA has begun enrollment. Case series in digital nerve repair have been published from the Mayo Clinic, Georgetown University Medical Center and Philadelphia Hand Center and a case series in OMF has been published from UT Southwestern. A number of additional investigator initiated case reports, studies and publications have been completed. A pilot study on the repair of the cavernous nerves in prostate cancer patients has completed enrollment and follow-up at Vanderbilt and data analysis and report are underway. Case series in brachial plexus, military trauma, neurotization of breast reconstruction and compressive neuropathy are also being developed. AxoGen also supports outside research and will continue to work with investigators working on grants with a translational focus.

Expand the AxoGen Sales Team

AxoGen provides full sales and distribution services through both a direct sales force and a team of independent distributors. As of December 31, 2015, we had 41 direct sales professionals and 24 independent distributors. AxoGen

provides support and resources for independent distributors both within and outside the United States and is increasing its direct sales force in selected United States territories. AxoGen provides products to hospitals, surgery centers and military hospitals, calling on plastic reconstructive surgeons and orthopedic and plastic hand surgeons and certain oral surgeons to review the benefits of the AxoGen products. While surgeons make the decision to implant the products in appropriate patients, hospitals make the decision to buy the products from AxoGen. In today’s budget constrained environment, hospital committees review new technologies for cost effectiveness as well as quality. AxoGen believes that it has been successful in meeting the needs of these hospital committees by demonstrating the cost/benefit of its products and providing a fair value to the hospital.

AxoGen Strengths

AxoGen believes that it has the following strengths in the field of nerve repair and regeneration:

Established Nerve Repair Expertise

AxoGen has made a significant investment in understanding peripheral nerve anatomy and surgical nerve repair and regeneration. This has been accomplished through interaction with leading academic centers throughout the United States and by striving to build an outstanding internal team of technical and clinical experts.

Commitment to the Promotion and Education of Best Practices in Peripheral Nerve Repair

AxoGen has established educational conferences and presentations and surgical resident and fellow training that we believe is positioning us as a leader in providing peripheral nerve repair best practices. The AcroValTM is a continuation of this commitment as we believe that an important step for improving patient outcomes is to support the standardized evaluation and measurement of nerve function. Ultimately, standardization of evaluation and measurement techniques will facilitate comparison and interpretation of clinical results leading to better understanding and care for patients with peripheral nerve injuries which can be incorporated into our educational programs and materials.

Surgical Implant Commercialization Experience

The AxoGen commercialization team consists of sales, marketing, and customer care professionals with backgrounds in the medical device and biotechnology industries. The team has strong experience in the introduction of technologies and has been instrumental in beginning to establish the Avance® Nerve Graft and the AxoGuard® product line as a new standard of care for the surgical treatment of nerve injuries. AxoGen believes it can leverage these capabilities in expanding the commercial success of the current AxoGen products and future product opportunities.

Avance® Nerve Graft Performance

AxoGen has worked with leading institutions, researchers and surgeons to support innovation in the field of surgical peripheral nerve repair. We believe AxoGen’s RANGER® study (defined below in the section entitled “Government Regulations”) is the largest multi-center clinical study conducted in peripheral nerve gap repair. AxoGen’s A Multicenter, Prospective, Randomized, Subject and Evaluator Blinded Comparative Study of Nerve Cuffs and Avance® Nerve Graft Evaluating Recovery Outcomes for the Repair of Nerve Discontinuities (“RECON”) study, the phase 3 trial to support its Biologics License Application (“BLA”), continues AxoGen’s clinical work, providing a new multi-center, prospective, randomized, clinical study on the Avance® Nerve Graft. (See “Government Regulations”). The January, 2012 edition of Microsurgery and November 2012 edition of The Journal of Hand Surgery and June 2015 edition of Journal of Reconstructive Microsurgery each contain an article summarizing the RANGER® study results. The Brooks et al. publication reported on 55 Avance® Nerve Graft nerve repairs and resulted in meaningful motor and sensory recovery in 87% of nerve discontinuities between 5 and 50 mm. Additionally, no implant related adverse events were reported. (Brooks, D. N., Weber, R. V., Chao, J. D., Rinker, B. D., Zoldos, J., Robichaux, M. R., Ruggeri, S. B., Anderson, K. A., Bonatz, E. E., Wisotsky, S. M., Cho, M. S., Wilson, C., Cooper, E. O., Ingari, J. V., Safa, B., Parrett, B. M. and Buncke, G. M. (2012), Processed nerve allografts for peripheral nerve reconstruction: A multicenter study of utilization and outcomes in sensory, mixed, and motor nerve reconstructions. Microsurgery, 32: 1—14. doi: 10.1002/micr.20975 and Cho, et al. 2012, J Hand Surg Am 37(11):2340-9). A meta-analysis of available clinical outcomes data from published

papers on the leading synthetic collagen conduit showed meaningful improvement in only 40-74% of cases bridging a gap in the nerve. A similar meta-analysis for nerve autograft reported meaningful improvement in 60-88% of nerve repairs.

International Opportunity for Product Sales

AxoGen currently focuses on the U.S. market, with additional foreign sales in Canada, Spain, Austria, United Kingdom, Israel, Greece, Chile, Switzerland and certain other countries. The need for the surgical repair of injured nerves is a global issue. Through its ex-U.S. sales, AxoGen has shown the capability to take its current nerve repair product offering into new geographical markets. AxoGen does not currently have European Union (“E.U.”) wide approval for Avance® Nerve Graft, but the AxoGuard® products have a CE Mark and can be sold in the E.U. and affiliated countries.

Research and Development

AxoGen believes it provides the most extensive product portfolio for peripheral nerve repair available. Our current development focus is to expand clinical data in both traumatic nerve repair and other surgical applications. Additional product line extensions of the Avance® and AxoGuard® products and other nerve repair products may be developed. In this regard, AxoGen introduced an AxoGuard® Connector line extension in winter 2014 by providing a new longer 15mm product. Our nerve evaluation and measurement tools are further examples of our development activity having launched the AxoTouchTM in the fall of 2014 and launching the AcroValTM systems in March 2016. AxoGen works with academic institutions in the expansion of treatments for peripheral nerve and is involved in a number of grants from government agencies related to nerve repair or use of our products and/or technologies. For the years ended December 31, 2015 and 2014, AxoGen spent approximately $3,237,000 and $3,033,000, respectively, on research and development expenses and recognized grant revenue of $433,000 and $314,000, respectively.

Competition

The medical device and biotechnology industries are characterized by rapidly advancing technologies, intense competition and a strong emphasis on proprietary products. As such, AxoGen cannot predict what products may be offered in the future that may compete with AxoGen’s products. With regard to nerve function evaluation and measurement there are a number of methods and techniques with little consistency of measurement protocols. Currently as to nerve repair products, AxoGen competes primarily against all transected and non-transected nerve repair approaches including direct suture repair, autograft and hollow-tube nerve conduits and materials used to wrap and protect nerve tissue. Because the requirements of the biomaterials used in nerve repair can vary based on the severity and location of the injury, the size and function of the nerve, surgical technique and patient preference, AxoGen’s nerve repair products compete against both autograft materials (nerve in the case of a bridging repair and vein or fat in the case of a nerve protection repair) and a limited number of off-the-shelf alternatives. Competitive aspects of our products focus on the overall value proposition of our products and their suitability for specific applications and can include composition and structure of the material, ease of use, clinical evidence, handling, and price. AxoGen’s major competitors for off-the-shelf repair options in hollow-tube conduits and bio-absorbable wraps are the following companies:

|

·

| |

Integra LifeSciences Holding Corporation (NASDAQ: IART) (“Integra”). Integra offers NeuraGen®, a hollow tube product made from reconstituted bovine collagen and NeuraWrapTM, a reconstituted bovine collagen biomaterial used for nerve wrapping; |

|

·

| |

Baxter International, Inc. (NYSE: BAX) (“Baxter”). Baxter acquired Synovis which offers Neurotube, a hollow tube made of polyglycolic acid; and |

|

·

| |

Stryker Corporation (NYSE: SYK) (“Stryker”). Stryker offers the NeuroMatrix and Neuroflex products, both of which are hollow tubes derived from reconstituted bovine collagen and NeuroMend, a reconstituted bovine collage biomaterial used for nerve wrapping. |

AxoGen believes that surgeons use Avance® Nerve Graft because it provides them with the natural three-dimensional structure and familiar handling characteristics of a typical nerve for bridging nerve discontinuities (severed

nerves) without the comorbidities and additional surgical site of an autograft as well as confidence in the performance of the product as a result of the growing body of clinical literature. AxoGuard® Nerve Protector and AxoGuard® Nerve Connector provide the unique features of pliability, suturability, and translucence for visualization of the underlying nerve while also allowing the patient’s own cells to incorporate into the extracellular matrix to remodel and form a tissue similar to the outermost layer of the nerve (nerve epineurium).

AxoGen believes any current or future competitors face the following important barriers to entry as it relates to the market for its nerve repair products. AxoGen’s intellectual property (“IP”), and that of its partners, including patents, patents-pending and know how, is believed to be an important barrier. Additionally, AxoGen has developed knowledge and experience in understanding and meeting FDA regulatory requirements for Avance® Nerve Graft, including having made a substantial investment in conducting the preclinical and clinical testing necessary to support a submission for a FDA BLA. However, due to its limited resources, its smaller size and its relatively early stage, AxoGen believes it may face competitive challenges and barriers that are difficult to overcome and could negatively impact its growth.

Intellectual Property

Overview

AxoGen relies on a combination of patent, trademark, trade secret, and copyright, as well as other IP laws, to protect IP rights. In addition, AxoGen utilizes license, non-disclosure, and assignment agreements to protect these IP rights. Specifically, AxoGen requires vendors, contract organizations, consultants, advisors and employees to execute nondisclosure agreements. AxoGen also requires consultants, advisors and employees who develop IP to assign to AxoGen any of their rights to all IP conceived in connection with their relationship with AxoGen.

License Agreements

AxoGen has entered into license agreements with University of Florida Research Foundation (the “UFRF”) and the University of Texas at Austin (“UTA”). Under the terms of these license agreements, AxoGen has exclusive worldwide licenses for the underlying technologies used by AxoGen in repairing and regenerating nerves. The license agreements include both the right to issued patents and patents pending in the U.S. and international markets. The effective term of the license agreements extends through the term of the related patents. In the event of default, licensors may also terminate an agreement (after written notice) if AxoGen fails to cure a breach. The license agreements contain the following key terms:

|

·

| |

Payment of annual license maintenance fees, some of which may be credited against future royalty payments; |

|

·

| |

Payment of royalty fees of 1%-3% based on net sales of the licensed products, the level depending on the agreement, which may include a minimum quarterly royalty payment with discounts off royalty rates when royalty stacking applies; |

|

·

| |

Payment of a percentage of sublicense fees received; |

|

·

| |

Reimbursement of certain legal expenses incurred for patent prosecution and defense; and |

|

·

| |

Other payments of various amounts based on achieving certain milestones. |

Currently, AxoGen pays royalties to UFRF and UTA specific to the licensed technologies related to the Avance® Nerve Graft.

Patents

As of the date of this Form 10-K, AxoGen owned or was the exclusive licensee of six issued U.S. patents, four pending U.S. patent applications, three issued international patents and nine pending international patent applications with regard to its peripheral nerve products. Additionally, the granted European Patent No. EP1425390 has been validated in France, Germany, Italy, Spain, Sweden, Switzerland, and the United Kingdom. The following table illustrates the issued U.S. patents owned or licensed by AxoGen with regard to its peripheral nerve products, including the patent number, a description of each patent, and the estimated expiration date of each patent.

|

|

|

|

|

|

|

Patent No.

|

|

Description

|

|

Estimated expiration date

|

|

|

|

|

|

|

|

US 6,972,168

|

|

Materials and Methods for Nerve Grafting, Selection of Nerve Grafts, and in vitro Nerve Tissue Culture

|

|

August 2021

|

|

|

|

|

|

|

|

US 7,402,319

|

|

Cell Free Tissue Replacement for Tissue Engineering

|

|

September 2023

|

|

|

|

|

|

|

|

US 7,732,200

|

|

Materials and Methods for Nerve Grafting, Selection of Nerve Grafts, and in vitro Nerve Tissue Culture

|

|

December 2022

|

|

|

|

|

|

|

|

US 6,696,575

|

|

Biodegradable, electrically conducting polymer for tissue engineering applications

|

|

March 2021

|

|

|

|

|

|

|

|

US 7,851,447

|

|

Materials and Methods for Nerve Repair

|

|

November 2023

|

|

|

|

|

|

|

|

US 8,545,485

|

|

Nerve Elevator and Method of Use

|

|

May 2032

|

Additionally, AxoGen entered into an exclusive distribution agreement with Cook Biotech in August 2008, as subsequently amended in March 2012, to distribute its ECM technology in the form of the Surgisis® Nerve Cuff, the form of a nerve wrap or patch, or the form of any other mutually- agreed-to configuration in the field of peripheral nervous system and central nervous system use, but excluding use of the AxoGuard® product in the oral cavity for endodontic and periodontal applications and oral and maxillofacial surgery solely as they relate to dental, soft or hard, tissue repair or reconstruction. AxoGen has subsequently rebranded the Surgisis products under the AxoGuard® name. Cook Biotech holds multiple issued and pending U.S. and international patents covering its ECM technology. The following table illustrates the two non-licensed U.S. patents held by Cook Biotech that are specifically identified on AxoGen’s AxoGuard® Nerve Connector and AxoGuard® Nerve Protector product labeling. The table includes the U.S. patent number, a description of each patent, and the estimated expiration date of each patent.

|

|

|

|

|

|

|

U.S. Patent No.

|

|

Description

|

|

Estimated expiration date

|

|

|

|

|

|

|

|

6,206,931

|

|

Graft Prosthesis Material

|

|

August 2017

|

|

|

|

|

|

|

|

6,241,981

|

|

Composition and Method for Repairing Neurological Tissue

|

|

September 2017

|

|

|

|

|

|

|

|

7,652,077

|

|

Graft Prosthesis, Materials and Methods

|

|

November 2018

|

|

|

|

|

|

|

|

6,358,284

|

|

Tubular Grafts from Purified Submucosa

|

|

December 2017

|

Because of the length of time and expense associated with bringing new products through development and the governmental approval process, medical technology companies have traditionally placed considerable importance on obtaining and maintaining patent protection for significant new technologies, products and processes. AxoGen intends to seek patent protection for appropriate proprietary technologies by filing patent applications when possible in the U.S. and selected other jurisdictions. AxoGen’s policy is to seek patent protection for the inventions that it considers important to the development of its business. AxoGen also intends to use its scientific expertise to pursue and file patent

applications on new developments with respect to uses, methods, and compositions to enhance its IP position in the areas that are important to the development of its business.

Trademarks, Trade Secrets, Copyrights and Domain Names

AxoGen has registered and filed numerous trademark applications with the U.S. Patent and Trademark Office and appropriate offices in foreign countries in order to distinguish its products from competitors’ products. It possesses trade secrets and material know-how in the following general subject matters: nerve processing, nerve repair, product testing methods, and pre-clinical and clinical expertise. AxoGen has registered copyrights for training tools and artistic renderings. It has entered into an agreement with an independent artistic creator, under which the artistic director retains copyright rights to any copyrighted material under agreement with AxoGen and provides AxoGen a license to such copyrights.

Government Regulations

U.S. Government Regulation Overview

AxoGen’s products are subject to regulation by the FDA, as well as other federal and state regulatory bodies in the U.S. and comparable authorities in other countries. In addition, its Avance® Nerve Graft must comply with the standards of the tissue bank industry’s accrediting organization, the American Association of Tissue Banks.

AxoGen distributes for Cook Biotech the AxoGuard® product line. Cook Biotech is responsible for the regulatory compliance of the AxoGuard® product line. AxoGuard® products are regulated as medical devices and subject to premarket notification requirements under section 510(k) of the Federal Food, Drug, and Cosmetic Act (the “FD&C Act”), 21 CFR Part 820 (“Quality System Regulation”) and related laws and regulations. Cook Biotech has obtained a 510(k) premarket clearance from the FDA for the use of porcine (pig) small intestine submucosa for the repair of peripheral nerve discontinuities where gap closure can be achieved by flexion of the extremity. Cook Biotech has also obtained a 510(k) premarket clearance for the AxoGuard® Nerve Protector for the repair of peripheral nerve injuries in which there is no gap or where a gap closure is achieved by flexion of the extremity. We sell the 510(k)-cleared device under the trade name AxoGuard® Nerve Protector and AxoGuard® Nerve Connector.

AxoGen also distributes the AxoTouch™ Two-Point Discriminator. This device that is manufactured for AxoGen and distributed from the Burleson Facility is a Class I device (general controls) that is exempt from premarket notification and the Quality System Regulation requirements except for the Recordkeeping and Complaint file requirements. It is classified by FDA under 21 CFR 882.1200 (Two-point discriminator, product code: GWI).

The AcroValTM line of devices will be manufactured for AxoGen and distributed from the Burleson Facility. The AcroValTM devices are regulated as medical devices and are subject to premarket notification requirements under section 510(k) of the FD&C Act. The AcroValTM line of devices includes the AcroGripTM, AcroPinchTM and PSSD, all of which received 510(k) clearance by the FDA in the 1990’s. The AcroGripTM was cleared under the name Digi-Grip Sensor, the AcroPinchTM was cleared as Pinch Sensor and PSSD as the NK Pressure-Specified Sensory Device.

In 2007, AxoGen began to process and distribute its Avance® Nerve Graft pursuant to Section 361 of the PHS Act and 21 CFR Part 1271 Human Cells, Tissues, and Cellular and Tissue Based Products controls. Such action was based on AxoGen’s good faith belief that the Avance® Nerve Graft product was a HCT/P tissue product regulated solely under Section 361. From October 2008 through early 2010, AxoGen was in communication with the FDA concerning the regulatory status of the Avance® Nerve Graft product. In April 2010, in response to a Request For Designation filed by AxoGen, the FDA determined that the Avance® Nerve Graft was a biologic product that would be reviewed and regulated by CBER under the requirements of Section 351 of the PHS Act. Section 351 requires, among other things, an approved license to market a biological product.

AxoGen met with CBER in July 2010 and, between July 2010 and November 2010, provided information to CBER that resulted in the FDA issuing a letter stating the agency’s intent to exercise enforcement discretion with respect to the introduction or delivery for introduction into interstate commerce of the Avance® Nerve Graft assuming that certain conditions are met relating to the transition of the Avance® Nerve Graft from regulation as a HCT/P to a biological

product under section 351 of the PHS Act. Specifically, the FDA is permitting the Avance® Nerve Graft to be distributed, subject to FDA enforcement discretion, provided that:

|

·

| |

AxoGen transitions to compliance with Section 501(a)(2)(B) of the FD&C Act, the current Good Manufacturing Practice, or cGMP, regulations in 21 CFR Parts 210 and 211 and the applicable regulations and standards in 21 CFR Parts 600-610 prior to initiation of a phase 3 clinical trial; designed to demonstrate the safety, purity, and potency of the Avance® Nerve Graft. |

|

·

| |

AxoGen has performed several gap analyses of its quality system for compliance with 21 CFR Parts 210/211 and 600-610 regulations. The gap analyses have identified areas in which our quality system could improve with respect to compliance to the regulations. The transition is in process and we periodically review the 21 CFR Parts 210/211 and 600-610 regulations to ensure that we create and implement appropriate changes, including new quality procedures. Through our internal auditing process, we periodically assess our compliance to the regulations. As AxoGen initiates the phase 3 clinical trial and eventual BLA submission, we will retain an external audit firm with experience in auditing to 21 CFR Parts 210/211 and 600-610 regulations to verify quality system compliance to the regulations. The associated costs for these activities are not material and the Company believes it can appropriately implement all necessary changes. |

|

·

| |

AxoGen conducts a phase 3 clinical trial to demonstrate safety, purity and potency of the Avance® Nerve Graft under a Special Protocol Assessment (“SPA”). |

|

·

| |

AxoGen and the FDA agreed to the SPA in August 2011 and in accordance with FDA regulations in 21CFR § Part 312, AxoGen submitted an Investigational New Drug Application (“IND”) to the FDA in April 2013. The IND became effective in March 2015 and the phase 3 clinical trial was initiated in the second quarter of 2015. |

|

·

| |

AxoGen continues to comply with the regulations and standard for 21 CFR Part 1271. |

|

·

| |

AxoGen was audited by the FDA at its processing facility in March 2013 and March 2015 and its Distribution Facility in October 2015. The quality system was found to be in compliance with 21 CFR Part 1271 and no FDA Form 483 observations were issued. |

|

·

| |

AxoGen continues to exercise due diligence in executing its requirements under the transition program. |

AxoGen is working to ensure compliance with the applicable regulations through ongoing discussions with the FDA regarding the transition of the quality system to 21 CFR Parts 210/211 and 600-610 regulations with the FDA and through audits for compliance to 21 CFR Part 1271 and amendments to the IND providing updates to the phase III clinical trial. The final determination of regulatory compliance will be made by the FDA during the pre-license inspection as part of the BLA review. If the FDA does not find AxoGen to be in compliance, or if AxoGen is unable to meet the required standards for preclinical studies, clinical studies and Chemistry, Manufacturing, and Controls, the approval of the BLA would become impossible or delayed.

The FDA will end the period of enforcement discretion upon a final determination of AxoGen’s future BLA submission or if the FDA finds that AxoGen does not meet the conditions for the transition plan, or is not exercising due diligence in executing the transition (e.g., study completion, or BLA submission is neither timely nor adequate). If final action on the BLA is negative or AxoGen is found to not meet the conditions for the transition plan or its execution, AxoGen will not be able to continue to distribute the Avance® Nerve Graft. AxoGen continues to work diligently with the FDA and, in this context, continues to distribute Avance® Nerve Graft.

The BLA application of Avance® Nerve Graft, if approved, will require a potentially substantial user fee payment to the FDA, although certain exemptions, waivers and discounts of the user fees may apply, including certain waivers or discounts for small businesses.

The Food and Drug Administration Safety and Innovation Act, referred to herein as FDASIA (Public Law 112-144), which was signed into law on July 9, 2012, amended the FD&C Act. FDASIA includes the Prescription Drug User Fee Amendments of 2012 which authorizes the FDA to continue to collect the following user fees from applicants who submit certain new drug and biological product applications and supplements:

|

·

| |

Application Fee: Each new BLA has a fee required upon submission. In FY 2016, this fee for a BLA requiring clinical data is $2,374,200. The fee is adjusted each year so we cannot provide an accurate estimate of what our fee will be upon submission of our BLA. For small companies (fewer than 500 employees and no other approved biologic product on the market) submitting its first application, a waiver of the application fee is available. AxoGen expects to apply for this waiver for the Avance® Nerve Graft BLA. |

|

·

| |